Blog

Designed For Greatness

Remarkable Results From Intentional And Holistic Design

Designing a pure, high powered theater .1/LFE subwoofer brings with it certain challenges and problems unique to the genre; similar to the differences between a road bike and a mountain bike or between a sport sedan and an off-road vehicle. So let’s jump in and see what some of those differences are and what our designers had to do to solve these challenges.

Designing a pure, high powered theater .1/LFE subwoofer brings with it certain challenges and problems unique to the genre; similar to the differences between a road bike and a mountain bike or between a sport sedan and an off-road vehicle. So let’s jump in and see what some of those differences are and what our designers had to do to solve these challenges.

We wanted HT to play exceptionally loud at a budget price, excel at speed because this is what delivers suddenness—the ability to startle—to special effects, and go quite low as many of modern soundtracks effects are being pitched lower and lower these days. The formula quickly defines itself; larger no-frills driver, very powerful amp for its price class, larger cabinet which reduces the energy needed to make higher output and a lightweight cone structure necessary for speed.

Right off the bat, we find ourselves constrained by a tight budget as many customers are seemingly limited or unwilling to spend as much for loud theater as they are for high quality music reproduction. This requires instant clarity of thought in design. Example, what do you do to control the massively reactive energy trapped in the driver itself which, left unchecked will cause the driver to literally shake itself to pieces over time?

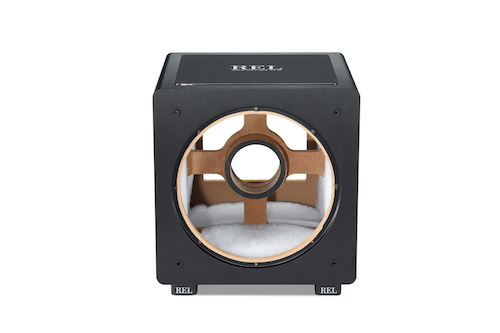

The affordable answer is to design an internal brace running from top of cabinet to bottom that cradles the magnet, is damped with soft synthetic wool to eliminate rattles and performs double duty by making the product more reliable to ship.

Speaking of the driver, how do you deliver a high energy/high output driver capable of around 110 db of output in an inexpensive package? You eliminate thick, expensive cast aluminum and more exotic alloys in the frame and go with lightweight stamped steel; powder-coat it so it won’t rust. The low mass cone means less magnet is needed. You get more clever, less “throw the kitchen sink at it” than you, as a designer might otherwise. The brace mentioned above then supports the rear of the driver so it won’t get damaged in shipping and quiets the resonances so more of the energy the driver produces translates into output.

In order to cope with all the output but deliver the kind of speed we experience in pro transfer studios, the cone had to be lightweight, rigid and clever as well. We created a new class of driver called CarbonGlas™ utilizing an inexpensive glasfibre primary cone and overlaid it with an expensive true carbon fibre inverted secondary cone that stiffens and quiets the cone. This combination produces tremendous speed capable of delivering the suddenness we insistent upon.

These techniques freed up enough room in the budget to step up from a 200-300w amplifier to a beastly 500w Class D amplifier capable of delivering huge output in our HT/1205 and a robust 300w in our super affordable HT/1003. These deliver output like subs that run 2-5 times what these units cost. The amps used are classics, have been around for a few years and have an excellent reputation for reliability.

Finally, we knew REL couldn’t get away with the made-in-your-cousin’s-garage fit and finish so many subs have suffered from over the decades. No “1973 called and they’d like their fake black ash vinyl back” for REL. We shaved cost in simple non-obvious ways that didn’t affect quality, like using large radii on our corners that allowed us to wrap the line grained aluminum-look composite in one continuous process saving over $100 at retail. The large radii also reduce the chances for shipping damage so another win all ‘round.

One item our designers have been delivering for the past decade or so is complex layering, it produces depth and interest when you look at one of our designs. Here, we were helped by the visual interest created in our driver design, the competing textures of the carbon fibre contrasting against the glasfibre needed something more; a matte black REL logo popped the whole effect, creating deep 3-dimensionality. Up top, where a customer’s eyes first take in the measure of a product, we inserted a high gloss lacquered panel that, again, produces contrast which we heightened by deliberately elevating the gloss panel thus breaking up the monotony of a planar surface. It also does a wonderful and affordable job of damping cabinet resonances so again, the theme of every part contributing double duty emerges. The final touch is always scaling the REL logo, when this is right, the whole design pops and suddenly we were done.

Of course, there are much more technical elements we undertook like custom developing proprietary filters to mitigate the driver-box resonance (produces FAR more low bass energy) but we’ll leave that for another day. In the end, we are enormously proud of developing something that sounds incredible for pure power theater (being a REL sounds pretty damned good in musical terms as well), that looks just right for its intended application, and all this at an exceptionally attractive pricing. Welcome HT.